How does temperature and humidity affect wood flooring in NZ?

Blog |

What is humidity?

When listening to the weather they often tell us what the relative humidity reading is. Relative humidity is a measure how full the air is with invisible water vapour at a particular temperature. Relative humidity of 30% indicates that the air not very full of water vapour and this represents quite dry conditions. Conversely, a relative humidity of 80% represents very moist conditions. Now, why this is important is because our timber floors react to the relative humidity in the air.

Timber is Hygroscopic

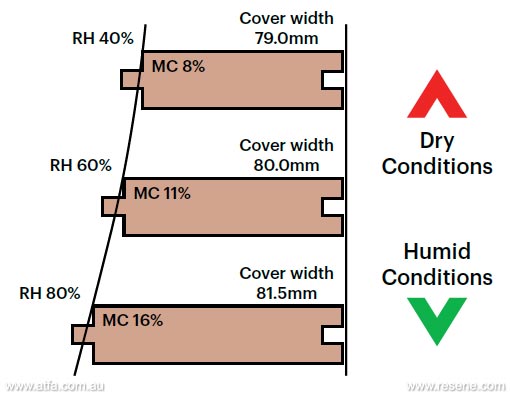

There are a number of building products that are hygroscopic and timber is one of them. A hygroscopic material will absorb moisture from the air when the relative humidity is high and in so doing the timber will expand. However, under low relative humidity conditions, the timber will release moisture to the air and contract. For a solid timber floorboard, this is illustrated in the adjacent diagram. You will see that if this 80mm wide floorboard was in conditions of 60% relative humidity then its moisture content (MC), the amount of water in the wood is 11%.

If the relative humidity of the air was to reduce to 40%, drier conditions, then water from the wood is released to the air reducing both the board width and its moisture content. However, a rise to 80% relative humidity, very humid conditions and the board will absorb moisture from the air increasing both its moisture content and width. Now, this is important because the relative humidity varies on both a daily basis and a seasonal basis, and this results in our flooring expanding and contracting throughout the year.

What is EMC?

Equilibrium Moisture content (EMC) is the moisture content that timber will approach under set conditions of relative humidity and temperature. At 60% relative humidity and 20°C the EMC is 11%, at 40% relative humidity and 20°C the EMC is 8% and at 80% relative humidity and 20°C the EMC is 16%, as shown in the diagram above. Now, if we had timber at 16% moisture content held in air that was 60% relative humidity at 20°C, then these conditions represent an 11% EMC. Under these conditions, the timber at 16% will release moisture to the air and reduce in moisture content until it is near 11%, and in so doing the floorboard will shrink.

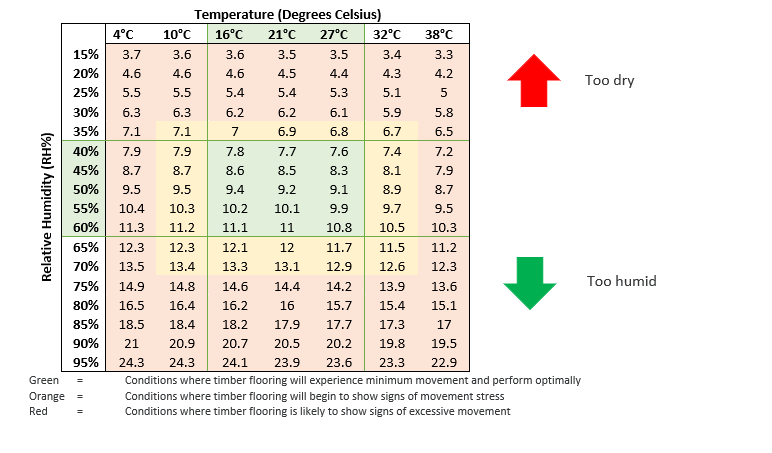

The timber industry has developed an EMC table covering a wide range of relative humidities and temperatures and as can be seen in the table below there is a sweet spot for engineered timber floors in New Zealand, signified by the green rectangle in the middle. This being conditions of 40% to 60% relative humidity and temperatures of 16°C to 27°C. Under these conditions our flooring will always remain within moisture contents of 7.6% to 11.1%.

What effect does temperature have?

It can be seen from the table that if the relative humidity stays the same then a change in temperature has little effect on the EMC. However, what we find is that a rise in temperature in a room will cause a drop in the relative humidity. Conversely, a drop in temperature causes a rise in relative humidity. So although it may be cold and wet outside signifying outside conditions of 8°C and relative humidity of 90%, on heating our home, very different conditions are created. Increasing the house temperature to 20°C the relative humidity will drop to say 55%, and these conditions with the ‘sweet spot’ for timber flooring shown in the table above.

Temperature has one other very important effect in that at higher temperatures timber will release moisture to the air or absorb moisture from the air (depending on the flooring moisture content and EMC) at a much faster rate than at low temperatures. So, relative humidity is the main factor in determining the moisture content that timber will adjust to, and the temperature influences how quickly it gets to that moisture content.

Timber in cold humid conditions will absorb moisture much more slowly than timber in hot humid conditions.

Our internal climate

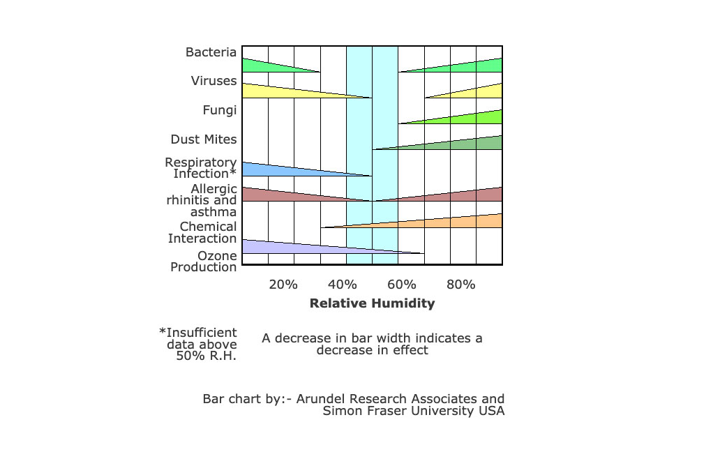

It is evident from this that our internal climate, the relative humidity and temperature range that is maintained, is extremely important as it dictates the performance of our engineered floors. If we maintain the correct climate signified by the green rectangle in the table above, it represents not only the conditions that our timber floors will perform best in, but it is also the conditions that we like to live in. This is also portrayed by health statistics as shown in the adjacent diagram where in conditions of 40% to 60% relative humidity a dwelling is less prone to bacteria and viruses and where conditions are less favourable to asthma and respiratory infections.

Issues with timber floors

Just as we are more likely to experience health issues at high and low relative humidity, such conditions are conducive to problems developing in timber floors. If the conditions are two dry our engineered floors with show splits in the surface layer. If relatively few in number this is not of concern, but of extensive then it is a concern and often brought about by a combination of too much heat and conditions also being too dry.

Our boards are also more likely to show shrinkage gaps at board edges. At the other end of the scale if conditions are too humid engineered flooring is prone to expansion-related problems. These include the centre of the boards rising higher the edges, known as crowning. The expansion pressure can also contribute to peaking at board end joints. This is where the end joints rise up. Again, this is often the result of the floor being exposed to prolonged higher humidity conditions during a warmer time of the year. Provided below are photos illustrating these concerns.

Preventing Issues

- Building Design Architect Consider humidity levels in the design phase.

- Product Selection Architect/Client Minimize movement through product selection.

- Control Climate Client Control the climate to minimize timber floor movement.

Building Design: Design the building to maintain humidity.

Prefinished engineered flooring with wire brushing and dried to the correct MC level in the manufacturing process is a robust product.

Product Selection: Minimize movement through product selection.

Prefinished engineered flooring with wire brushing and dried to the correct MC level in the manufacturing process is a robust product.

Factors to consider when selecting timber flooring:

- Higher Density timber are more prone to checking (i.e, Teak)

- Solid timber is a lot more prone to checking/movement

- Floated flooring is a lot more prone to movement

- Thinner veneers (less than 3mm) are more prone to checking/crowning as they have less integral strength)

- Smooth surfaces will show checking, whereas even lightly brushed surfaces will disguise checking for the unaided eye

- Dark colours will absorb heat faster, making them more prone to movement

- Purchase engineered timber flooring, not solid timber

- Glue-down rather than floating installation method

- Select a brushed surface rather than a smooth surface (a smooth surface will show checking more prominently)

If you believe your home is high-risk, speak with your Forte representative. You should ideally select a thicker veneer and narrower plank so the flooring has additional structural integrity and can cope with additional pressure/stress caused by the more challenging conditions.

Control Climate: Control the climate to minimize timber floor movement.

If the conditions outside are very dry (i.e., Winter in Central Otago) then the EMC will be on the lower range. When designing houses in dry climates, it is important to consider;

- Consider using radiant heating (i.e., water-controlled radiators, hydronic underfloor heating, and electric heaters) rather than air-conditioning units as air-conditioning dries out the air further.

- Consider installing a humidification control system if you have the budget.

- Other simple and practical measures include, adding houseplants that you water regularly and purchasing a portable humidifier/vaporizer.

If the conditions outside are very humid/moist (i.e., Summer in Auckland) then the EMC will be on the higher range. When designing houses in humid climates, it is important to consider installing an HRV system.

You can monitor the EMC to ensure it is maintained within acceptable levels by purchasing an inexpensive temperature/humidity tracker.

Visit one of our Showrooms

If you have any queries about our products or need help with your project, we can provide you with expert advice. Visit one of our showrooms or book a consultation with our flooring experts today.