5 Differences between Engineered Wood and Laminate Flooring

Blog |

If you’re looking for an affordable alternative to solid wood flooring, engineered timber and laminate flooring have likely crossed your mind. At a glance, they do share similarities but in practice, they couldn’t be more different.

In this article, we explore five differences between these products to help you make an informed investment for your project.

What is Laminate flooring?

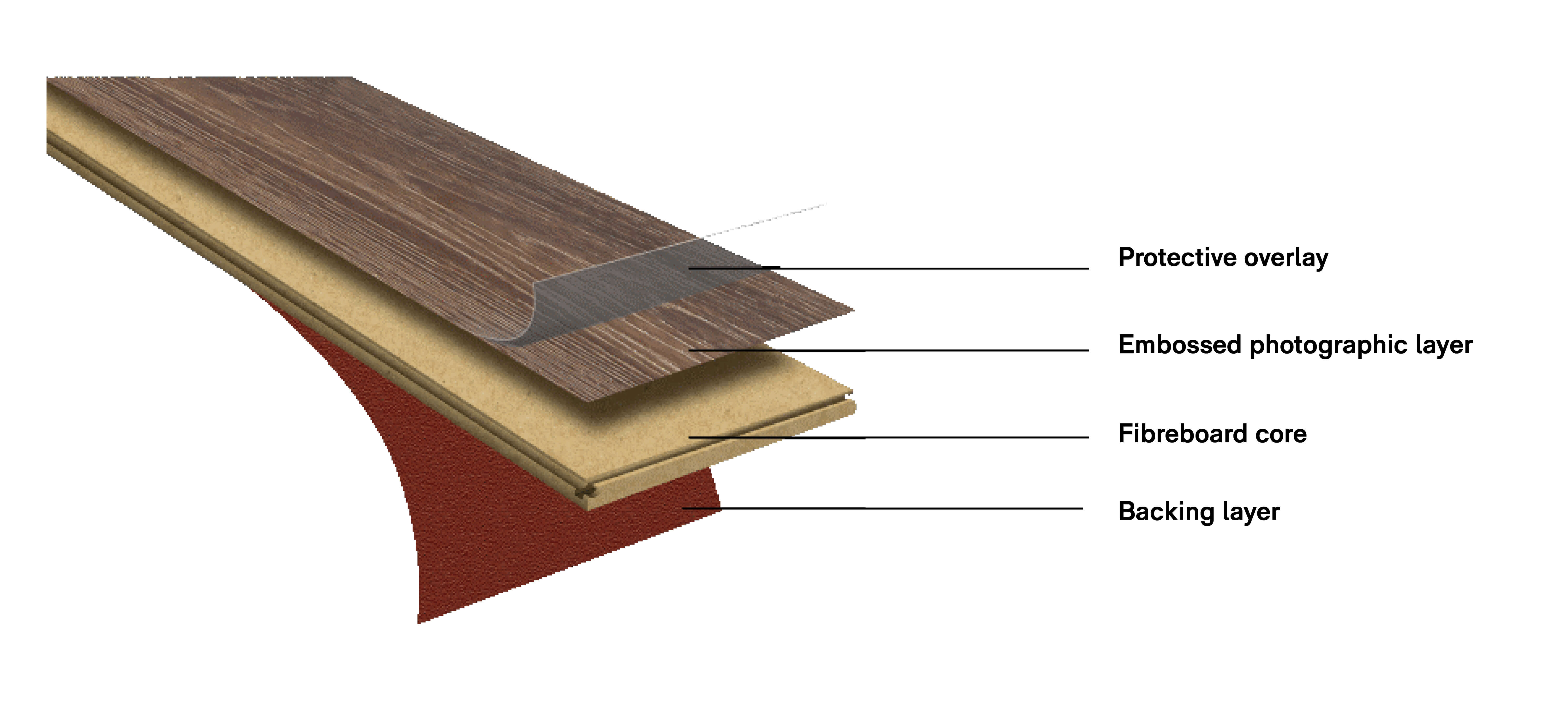

Laminate is a man-made synthetic material made of many layers fused together through lamination. The flooring base is fibreboard and the top is a photographic applique layer that mimics real wood. This is coated with a strong, clear resin to provide protection.

What is engineered wood flooring?

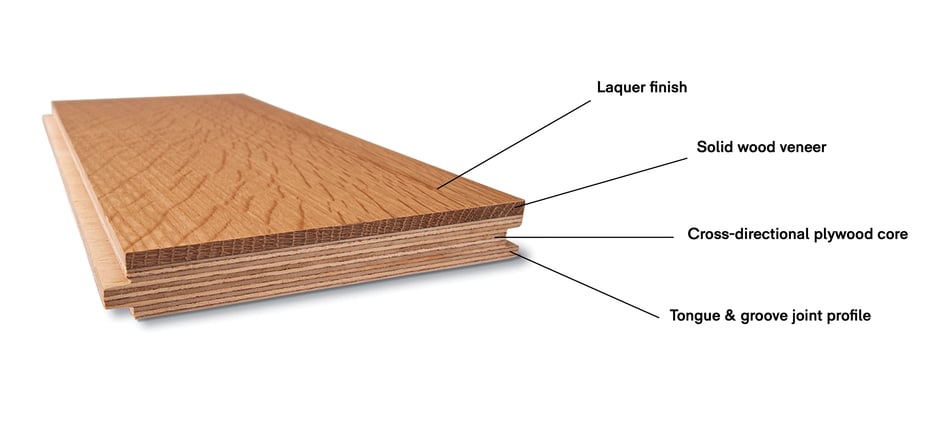

Engineered wood consists of a solid hardwood veneer fixed to a multi-layered backing. The backing is usually made of multiple layers of more cost-effective timber that is glued cross-directionally and pressed together for strength.

Engineered wood flooring planks feature a tongue and groove joining profile. The ‘grooves’ are cut into one long side and one short side and the ‘tongues’ stick out on the opposite sides. These pieces slot into each other and hold the flooring together.

What is a wear layer?

A wear layer, or veneer, is the top layer on an engineered wood flooring plank and is located above the tongue. This determines how often the flooring can be re-sanded because you can only sand as far as the top of the tongue.

The thickness of the wear layer also affects the number of re-sands the flooring can have. The thicker the veneer, the longer it will last. Most engineered wood flooring has between a 2mm and 6mm veneer of real wood, and the most common thickness is 4mm, with enough timber for up to 3 re-sands over its lifespan.

5 differences between engineered wood & laminate

1. Appearance

Although the aesthetic of laminate has improved in the last few years, it is still a replica. The photographic applique layer bears a resemblance to real wood but there are repetitive patterns and features that don’t look natural, such as knots and cracks.

Engineered wood flooring is the real deal. The top layer is made of genuine hardwood, offering a variety of colours, grades, textures, and finishes, with no repetitive planks. Nothing brings warmth, heritage and natural character to your interior space like a real hardwood floor.

Another consideration is the appearance of the joins between each plank. In large areas, there is a high risk that laminate boards will expand and contract, requiring expansion trim on each join. With engineered hardwood, the tongue and groove joints are strong, smooth, and seamless.

2. Sound and feel underfoot

Laminate flooring is installed ‘floating’ over the subfloor and a foam underlay, which can cause the floor to flex underfoot as you walk. This can create a hollow cracking sound and an echo throughout the space. Laminate is also known for amplifying the ‘click-clack’ sound of heels and pets with untrimmed nails.

Engineered wood flooring is usually glued down for increased stability. This eliminates the creaking and cracking underfoot, making it feel and sound better to walk on.

3. Durability and lifespan

Depending on the quality, laminate flooring has a lifespan of around 10 to 20 years. When it is damaged, it cannot be sanded or refinished so your only option is to replace it. Additionally, the boards and joints are prone to buckling and separating under heavy items, such as pianos or pool tables.

In comparison, engineered wood flooring is finished with a factory-applied sealant to protect it from damage and moisture. Depending on the thickness of the veneer, each plank can be re-sanded multiple times, giving it an impressive lifespan of 25 to 50 years.

Installing wood floors in wet areas

Since the building code change to E3 came into effect at the end of 2021, there is a misconception that vinyl flooring is the only ‘wood-look’ flooring option suitable for wet areas like kitchens. However, engineered timber flooring can still be used in wet areas, as long as the floor is installed in accordance with E3.

While laminate can be installed in some wet areas, the boards must be tightly sealed because any moisture that penetrates the lower fibreboard core will cause it to swell and deform. However, the reinforced base core of engineered hardwood flooring is dimensionally stable, making it more resistant to swelling and expansion when it is exposed to moisture.

4. Resale value

Laminate flooring tends to have a negative impact on the resale value of your home. Although it is better than it used to be, many people are turned off by vinyl flooring due to its short lifespan, tacky appearance, and hollow sound and feel underfoot.

However, engineered wood flooring adds to the resale value of a home by enhancing the sense of luxury and quality. It can be a real selling point as it provides a high-level finish, authentic appearance, a longer lifespan, and better sound and feel underfoot.

5. Sustainability

Laminate flooring is made from synthetic material and a base fibreboard which is produced by crushing up pine and mixing it with a type of glue or resin. Although some manufacturers use some renewable materials, the glue contains various toxins and, if the vinyl is not FSC or PEFC certified, it may be harvested from forests with unsustainable processes.

Both the solid wood veneer and plywood base of engineered wood planks are environmentally friendly. Compared to a solid hardwood floor, the veneer uses far less timber per plank and the plywood backing is one of the most fast-growing and renewable wood resources on the market.

Additionally, the manufacturing process of engineered wood flooring does not involve any toxic glues.

Engineered wood flooring NZ

Although engineered timber flooring comes at a higher cost, the benefits far outweigh those of laminate flooring. Laying engineered wood in your home is a wise investment, bringing warmth and character that you will enjoy for decades to come.

Here at Forté, we supply a wide range of engineered hardwood flooring for a variety of environments and applications. Every board is engineered for maximum durability to ensure years of practical, low-maintenance use. Every board is pre-finished, sustainably sourced, low in formaldehyde, and can be re-sanded up to three times.

Contact us to find out more about our flooring collections or get expert advice for your interior space. We’ll share our industry tips and recommendations to get you started and can even send you a free box of flooring samples to help you choose.

Visit one of our Showrooms

If you have any queries about our products or need help with your project, we can provide you with expert advice. Visit one of our showrooms or book a consultation with our flooring experts today.